Designed with efficiency in mind, the welding x ray machine combines exposure control and image processing. The equipment enables the observation of detail in both the bone and soft tissues without much distortion. The welding x ray machine offers high flexibility when it comes to operations and can work well in various settings like hospitals and research labs.

Apart from traditional diagnostics, the welding x ray machine is applied in interventional procedures to assist physicians in minimally invasive treatments. It provides real-time imaging during catheter placement, spinal manipulations, and orthopedic implant confirmation. The welding x ray machine enhances the accuracy of the procedure and patient safety in complex medical procedures.

The welding x ray machine will be revolutionized through AI-based image analytics, enabling faster diagnostic reporting and decision-making assistance. Miniaturization of sensors will lead to ultra-portable hardware in emergency and field medicine. The welding x ray machine will redefine medical imaging with higher accuracy, velocity, and interconnectedness for healthcare networks.

Cleaning and calibration are necessary to maintain the welding x ray machine. Surfaces should be cleaned with certified disinfectants to prevent contamination. The welding x ray machine should be tested from time to time to determine performance stability. Electrical grounding and cooling fans also need to be checked periodically to provide safe and efficient service.

The welding x ray machine has been used heavily in various medical fields due to its ability to offer rapid and precise medical images. The welding x ray machine offers precise images of the various body parts that help in the diagnoses of various conditions such as bone injuries, cancer, and infections. The welding x ray machine uses advanced imaging softwares that offer high contrast images.

Q: What are the main components of an x-ray machine? A: The main components include the x-ray tube, control panel, collimator, image receptor, and protective housing, all working together to produce diagnostic images. Q: How should an x-ray machine be maintained? A: Regular inspection, calibration, and cleaning are essential to keep the x-ray machine operating accurately and safely over time. Q: What industries use x-ray machines besides healthcare? A: X-ray machines are also used in security screening, industrial testing, and materials inspection to identify defects or hidden items. Q: Why is calibration important for an x-ray machine? A: Calibration ensures that the machine delivers accurate radiation doses and consistent image quality, which is crucial for reliable diagnostics. Q: How long does an x-ray machine typically last? A: With proper maintenance, an x-ray machine can remain operational for over a decade, depending on usage frequency and environmental conditions.

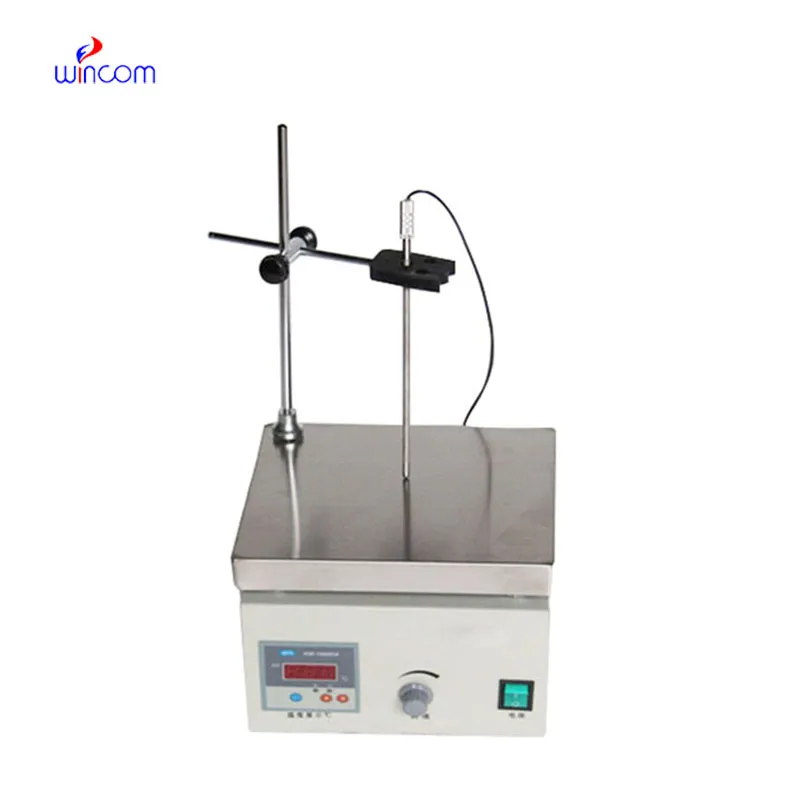

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

I’ve used several microscopes before, but this one stands out for its sturdy design and smooth magnification control.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China