Its superior optics enhance observation precision with crisp, high-resolution images at every magnification. Its durable construction resists frequent use in the classroom and professional environments. The variable brightness and focusing adjustments make the pathogen microscope suitable for many types of specimens, from biological tissues to industrial samples. Optional digital accessories extend its functionality with high-resolution imaging, data storage, and analytical interface with modern research systems.

Across the worlds of science, industry, and education, the pathogen microscope enables research at the microscopic level. It is an essential tool in medical diagnosis to analyze blood, tissues, and pathogens. Environmental scientists apply the pathogen microscope to determine bacteria and microalgae that indicate water levels of quality. In materials science, it enables nanostructure analysis and the identification of defects. Art conservators apply the pathogen microscope to analyze pigments and varnish layers. Its ability to produce accurate, detailed imagery makes it a valuable resource in continuing discovery and research development.

Future technology is revolutionizing the future of the pathogen microscope, focusing on automation, high speed, and visualization. New-generation models will be provided with sophisticated image-processing algorithms to process information in real time. The pathogen microscope will likely utilize adaptive optics for improved imaging at higher magnifications, both to the advantage of biological and materials research. Handheld and portable versions will become standard, bringing microscopic study to the location. With growing demands for sustainability, energy-saving pathogen microscope versions will also run laboratories worldwide.

Cleaning, checking, and storing the pathogen microscope with care is part of taking care of them. Dust accumulation can impact both optical and mechanical performance, and thus covering the pathogen microscope when idle is inevitable. Avoid handling objective lenses with unmasked fingers to prevent oil smudges and residues. Remove immersion oil instantly after observation. The pathogen microscope are kept in a controlled, temperature-stable environment. Periodic focus and illumination system calibration ensures image quality in the long term.

The pathogen microscope allows researchers to study the world at a microscopic level with stunning detail. Using high-tech optical or electron systems, the pathogen microscope magnifies samples to reveal texture, layers, and details that are imperceptible to the human eye. From life sciences to factory quality control, uses span the range. Portable and compact models now combine ergonomic design and digital controls to offer comfort, accuracy, and dependability for extended observation periods.

Q: What distinguishes a digital microscope from a traditional one? A: A digital microscope integrates cameras and imaging software, enabling users to view, capture, and analyze images directly on a computer or monitor. Q: How can vibration affect a microscope? A: Vibration can cause image blur or misalignment, so the microscope should always be placed on a stable, vibration-free surface. Q: What safety measures should be taken when using a microscope? A: Avoid touching optical parts with fingers, use slides carefully, and ensure electrical components are safely connected before operation. Q: Why is immersion oil used in some microscopes? A: Immersion oil increases the refractive index between the lens and specimen, improving resolution and brightness at higher magnifications. Q: How can you prevent mold growth in a microscope? A: Store the microscope in a low-humidity environment and use desiccants or dehumidifiers to keep optical components dry and mold-free.

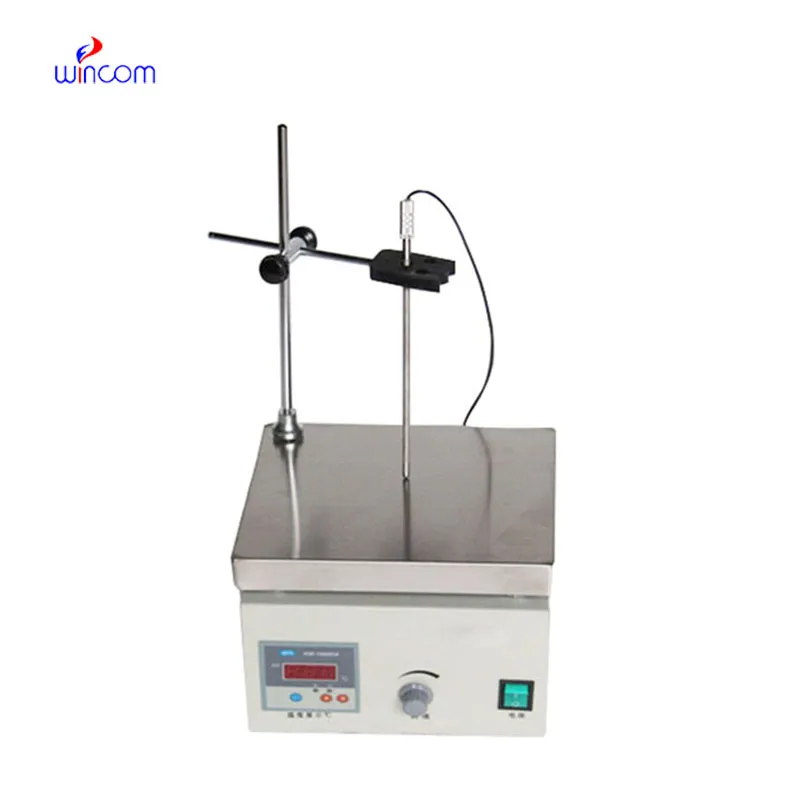

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China